construction plan

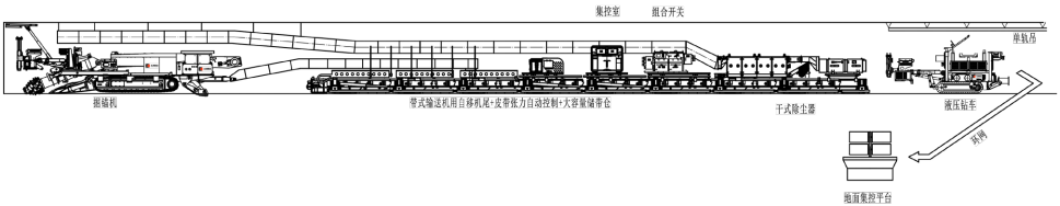

Bolt digger + remote intelligent control system + hydraulic anchor drill + self-moving tail for belt conveyor + crawler transport vehicle/pneumatic light monorail crane

Construction technology

1. The bolt digger performs cutting, temporary support, anchor bolt and cable support, and head-on drilling operations.

2. The hydraulic anchor drilling rig installs anchor cables behind the windlass digger and performs monorail crane installation operations.

3. The tail of the self-moving belt conveyor is equipped with a dust removal system to automatically move forward.

4. Crawler transport vehicles or pneumatic light monorail cranes are responsible for the head-on transportation of small equipment and materials.

5. Equipped with an intelligent dry (wet) dust collector to monitor and control dust during excavation.

6. The remote intelligent control system performs remote control operations on the tunnel boring machine and has functions such as video monitoring, status monitoring, fault diagnosis, audible and visual alarms, posture monitoring, and automatic cutting.

Technical features

1. Reducing manpower: There are fewer people employed in support, transportation and other links, and the number of people working head-on shall not exceed 9

2. Efficient: Multiple units cooperate with mechanized operations to increase the excavation efficiency by more than 30%.

3. Labor saving: The labor intensity of employees is significantly reduced.

4. Safety: The comprehensive mechanization level is high, and the operation safety is significantly improved.

Hot News

Hot News